PCM Maintenance Solutions - Reduce Downtime & Costs

Looking to reduce your maintenance costs? Do you want to optimize and secure your PCM systems for long-term performance?

What Is PCM Hygienic System Maintenance?

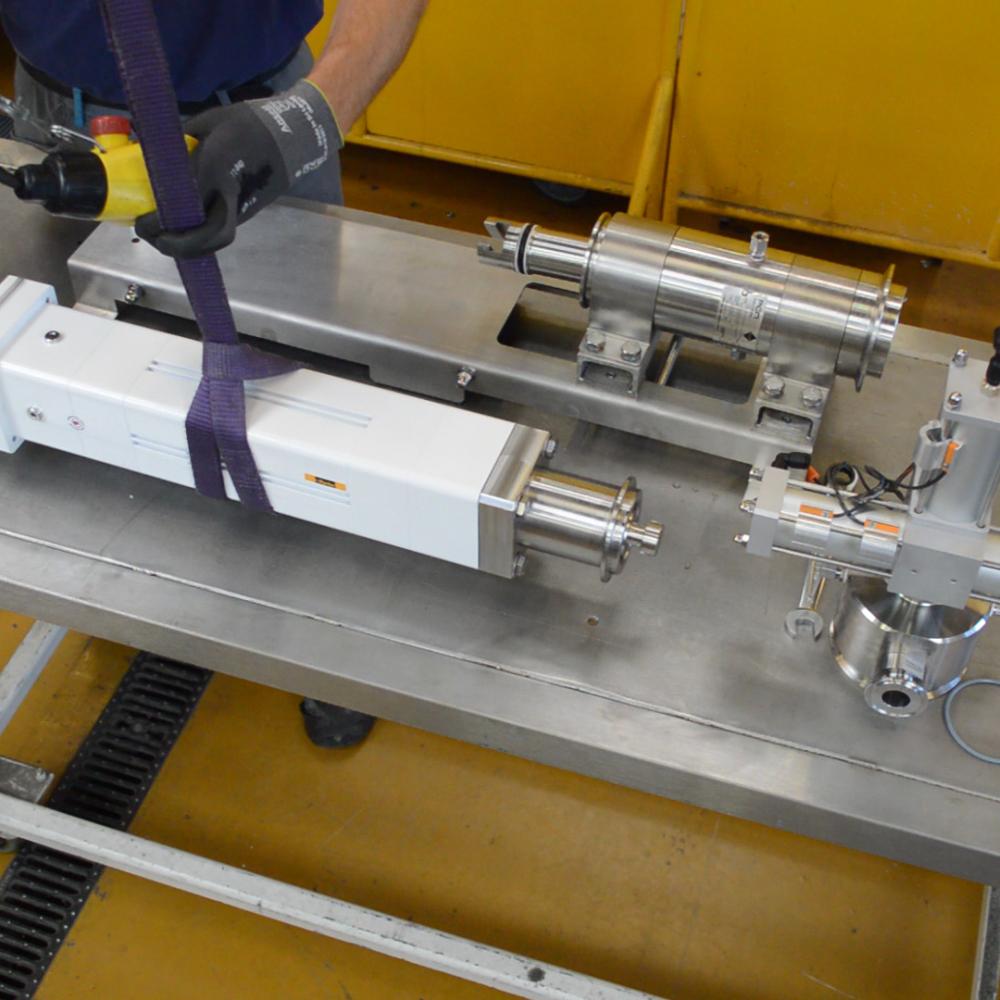

PCM’s maintenance service ensures your systems operate at their best. Our teams provide on-site and remote maintenance, including system expertise and tailored training.

The goal is simple: ensure reliability, extend equipment life, and reduce operating costs.

Why maintain your system?

These services provide:

- Optimized and secure production performance

- Quick access to a team of experts on-site or remotely

- Extended guarantees following interventions

- Lower operating costs and optimized spare parts inventory

- Access to maintenance training tailored to your operational needs

Maintenance training

Would you like to learn more about the maintenance and operation of your systems?

PCM teams share their technical expertise during training courses tailored to your needs.

Organized by theme, they take place on site or remotely for maintenance and production staff.

Contact us to know more about trainingNeed maintenance support?

Whether it’s preventive or corrective, our experts are here to secure, optimize, and extend the life of your PCM systems — on-site or remotely.