Turnkey System for Product Filling

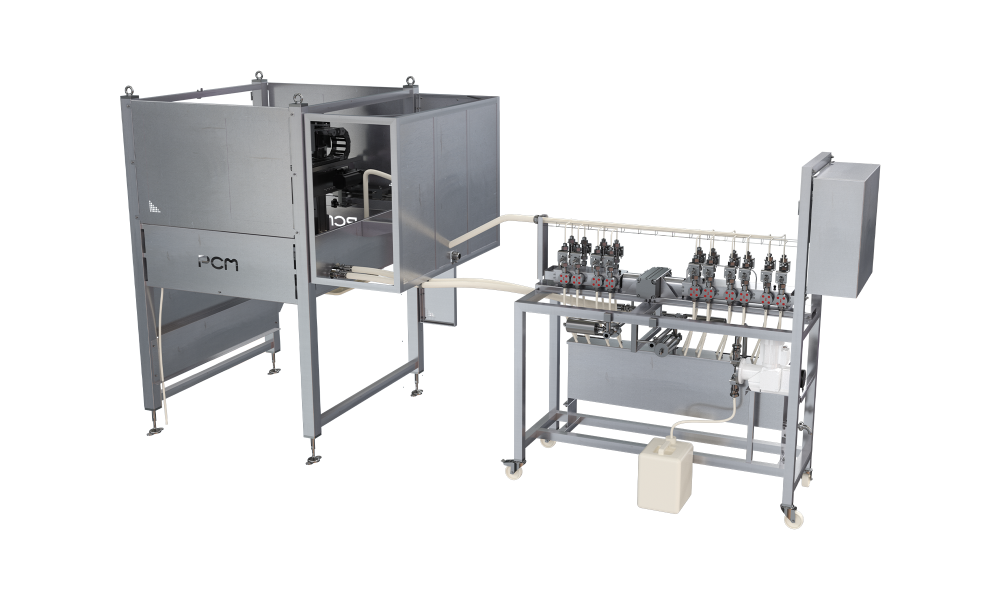

PCM Dosyfeed & Additivefeed

At PCM, fodder is not just about injecting an ingredient: it is a total solution that enhances the value of your products while optimising your production line. Our turnkey offer combines Dosyfeed and Additivefeed technologies to meet all your dosing and topping needs

The PCM Dosyfeed system allows the filling of viscous or heterogeneous ingredients such as jams, honey, chocolate into rolls.

The PCM Additivefeed system will be more suitable for filling homogeneous liquid flavors in various bakery preparations.

Why opt for a tailor-made solution?

- Adapted to your products and processes : Volume to be dosed , type of filling or packing (liquid, viscous, stringy, heterogeneous), speed

- Choice of technology : Dosys™ or MDS membrane, depending on production constraints.

- Easy integration : takes into account the existing space, dimensions and conveyor widths.

- Maximum reliability : precise and repeatable dosing, even at high speeds.

- Hygiene guaranteed : sanitary design, cleaning in place without dismantling.

Two technologies adapted to your recipes

PCM Dosyfeed

The ideal choice for filling viscous products or products containing pieces such as jam, honey, caramel or chocolate.

It is based on:

- Dosys™ technology, known for its dosing accuracy and repeatability

- Customizable drip and needle nozzles (single or multiple stitching)

- A hygienic and fully automatable system

PCM Additivefeed

Specially designed for homogeneous liquids such as syrups, flavourings or liqueurs. It allows:

- Smooth dosing synchronized with the packaging line

- The use of membrane multi-dosing units (MDS) for maximum flexibility

- Compact, mobile design that's easy to integrate

INDUSTRY

INDUSTRY

BENEFITS

APPLICATION

TO KNOW MORE

Bakery & Pastries

Bakery & Pastries

Precision, pace, respect for texture

Pastry cream in cream puffs

Bakery & Pastries

Bakery & Pastries

Low-flow accuracy, flexible flow adjustment

Flavoured syrup in rolled cake

Bakery & Pastries

Bakery & Pastries

Precision, speed, versatility, clean-in-place

Caramel, chocolate or fruit filling in doughnuts

Let’s build the solution together that will make your products benchmarks in their market.

With its expertise in pumps and food systems, PCM supports you in developing a forage line tailored to your constraints, production rate, and creative ambitions.

FAQ – Turnkey System for Product Filling