Dynamic mixing, without compromise

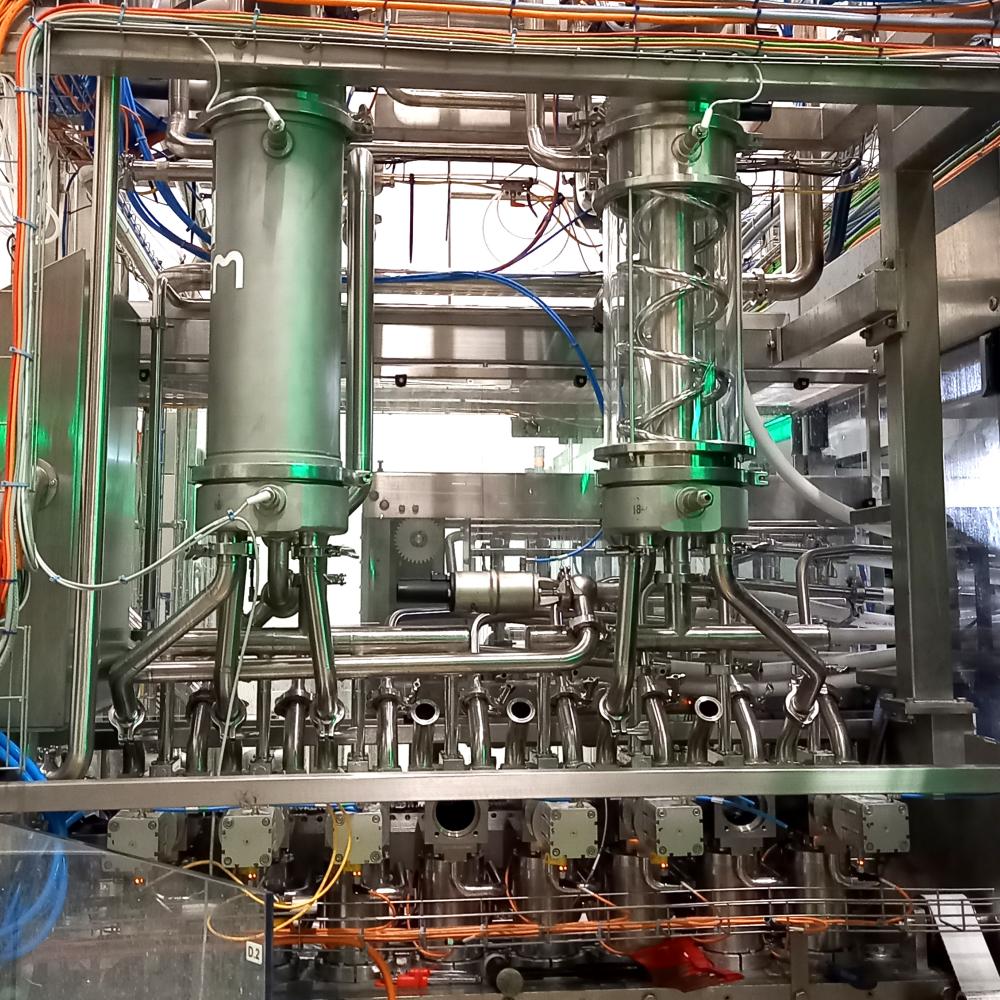

PCM Dosymix™

Perfect homogeneity, online and without downtime

In the food industry, mixing liquid or semi-liquid ingredients is a critical step, often time-consuming and energy-intensive.

The PCM Dosymix™ allows in-line mixing, without the need for a tank or traditional mechanical agitation, with an unrivalled level of precision and hygiene.

Thanks to its unique technology, you achieve a continuous, controlled, clean and compact mixing.

The key benefits of PCM Dosymix™

- Respect for sensitive products : ideal for mixtures of products containing markings or fragile ingredients, thanks to rounded non-stick impellers.

- Excellent product compatibility : suitable for mixtures of various viscosities and proportions (colouring in a foamed foam, pulp in drinking yoghurt, fruit on sugar in white mass, flavouring in fresh paste)

- 3A certified hygiene : sanitary design, CIP/SIP facilitated.

- Reduction of losses : delayed finalization of the final product at the last moment. low internal volume, limiting residues at the end of the cycle.

- Multiple outputs : precise distribution to the packaging dispensers

- Quick maintenance: simple disassembly via tri-clamp coupling, standardised cartridge seal.

- Shared components: mechanical seal identical to that of PCM HyCare™ progressive cavity pumps.

How does the PCM Dosymix™ work?

The mobile (consisting of two propellers with opposing pitches welded to a shaft) allows for gentle mixing to care for ingredients and distribute markers accurately.

The residence time in the mixer body (measured in seconds) ensures the quality of the mix. This residence time depends on two factors : the internal volume of the PCM Dosymix™ mixer and the production rate in m3/h.

Special DMR Hopper Dosymix™

- 2 Functions in 1: Buffer hopper + dynamic in-line mixing

- Ideal for just-in-time operation as a buffer hopper replacement for preformed container packers

- Less waste, more flexibility in recipe changeovers

- Easier cleaning, with no buffer tanks or isolation valves to manage

- Fast integration on existing line

INDUSTRY

INDUSTRY

BENEFITS

APPLICATION

TO KNOW MORE

Dairy

Dairy

Respect for the texture, no marbling, homogeneous mixing

Cream and retentate in dairy base

Dairy

Dairy

Respect for the texture, no marbling, homogeneous mixing

Ferment, vitamins, minerals in fresh dough

Petfood

Petfood

No mottling, homogeneous mixing

Cruor, caramel, iron oxide in cured meat stuffing

Sugar & Starch

Sugar & Starch

No mottling, just-in-time differentiation

Concentrated flavourings (mint, coffee) in chocolate before moulding

Gain agility, compactness and performance with PCM Dosymix™

PCM Dosymix™ is the ideal solution for mixing, without batching and without compromise. Compact, hygienic and automatable, it adapts to your recipes, your lines and your quality requirements.

To configure a standard Dosymix™ system or a hopper that is perfectly integrated into your processes.

FAQ – PCM Dosymix™