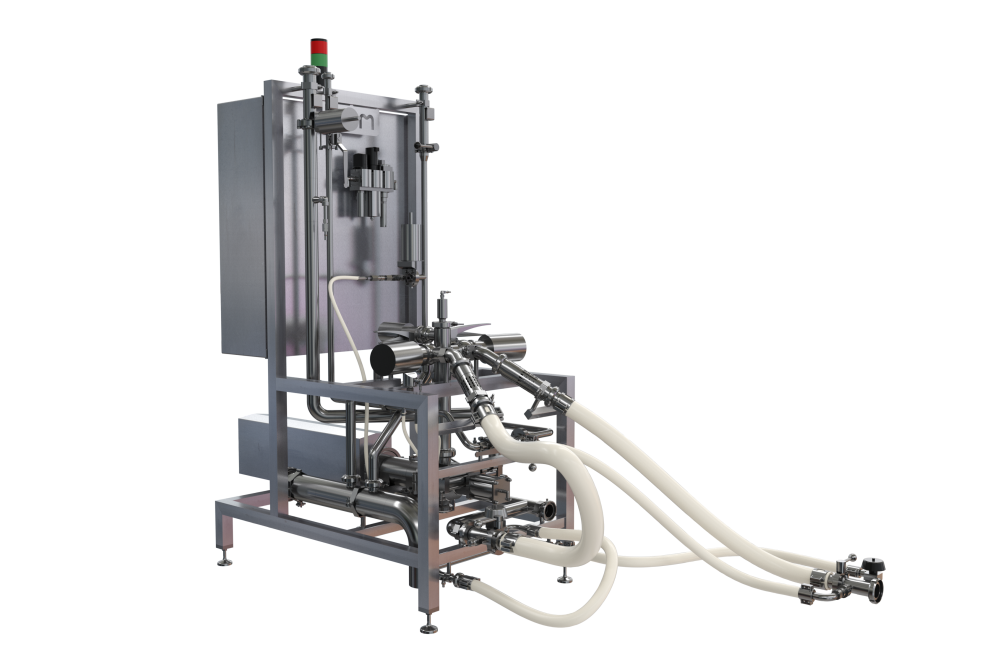

Single or multi-ingredient dosing system

PCM Dosyfruit™

An expert solution for injecting fruit and heterogeneous ingredients into yoghurts and fresh products.

In the production of fruit yoghurts, dairy desserts, and other fresh products, precise ingredient dosing is essential to ensure product quality, consistency, and optimal yield.

PCM Dosyfruit™ is the industry benchmark for dosing fruits, syrups, flavourings, and preparations with particulates or visual markings—directly into dairy bases or similar food matrices.

Why choose PCM Dosyfruit™?

- Intelligent CIP control and cleaning in place for controlled hygiene (automatic in Premium, or basic version).

- Multi-recipe flexibility : easy adaptation to production changes.

- Precise dose adjustment (automatic with Brushless in Premium or manual with pneumatic actuator for the basic version).

- Optimized recipe changes : Optimized management of "fruit-on-fruit" shoots to minimize losses.

- Containers Automatic changeovers without stopping production.

- Product recovery at the end of the cycle thanks to water proofing before cleaning.

- Reliable and repeatable dosing with patented Dosys™ technology.

- Respect for sensitive ingredients, with or without markings.

PCM Dosyfruit™ Premium

PCM Dosyfruit™ premium is a single or multi-ingredient dosing system with dispensing in BIBs or containers whose operation is fully automated. It is therefore the reference for the injection and dosing of fruit in fresh dairy products.

Key Benefits

- Full automation : cleaning, sterilizing and priming of sleeves, container tipping and CIP managed without intervention, for continuous production.

- Automatic dose adjustment thanks to the Brushless actuator, for fast and error-free dosing.

- Optimal flexibility : easy multi-recipe management, ideal for highly variable lines.

- Reduction of material losses : intelligent "fruit on fruit" or "water on fruit" transitions, product recovery at the end of the cycle.

- Synchronized and ultra-precise dosing: Dosys™ + Brushless technology, avoiding overdosing.

- Maximum hygiene : automatic cleaning and sterilization (sterile air, steam, filtration), right down to the container valves.

- Total respect for the ingredients, even the most sensitive or marked, without alteration.

Typical applications

- Multi-layer fruit yoghurts

- Dairy products with flavourings or inclusions

- Fresh desserts with pulps or scorching

PCM Dosyfruit™ Basic

PCM Dosyfruit™ basic is a single-ingredient injection system with racking in BIB or containers. This cost-effective solution is perfectly suited to installations in the fresh dairy industries.

Key Benefits

- Manual priming, auto-failover (optional)

- Manual dose adjustment (pneumatic actuator)

- CIP autopilot

- Multi-recipe and adaptable

- Reduction of losses (fruit growth/water, product recovery)

- Reliable dosing with Dosys™

- Respect for sensitive ingredients

Typical applications

- Flavoured yoghurts

- Single-ingredient preparations in containers or BIBs

- Artisanal or modular packaging lines

INDUSTRY

INDUSTRY

BENEFITS

APPLICATION

TO KNOW MORE

Dairy

Dairy

Precision, respect for pieces, clean-in-place

Fruit on sugar in stirred yoghurt, cream cheese

Dairy

Dairy

Precision, clean-in-place, easy servo control

Fruit pulp in drinking yoghurt, stirred yoghurt

Cosmetics & Personal Care

Cosmetics & Personal Care

No production downtime (automatic change of empty IBCs)

Hair gel resins (1000 kg IBC)

Health & safety at the heart of the design

- Complete hygienic design (CE 1935/2004 – FDA),

- Closed and sterilizable circuits,

- Materials certified for food contact,

- Sterile air, steam, or automated CIP integration possible.

Inject precision into your line

With PCM Dosyfruit™, you are in control of every dose, every recipe and every cycle, while ensuring maximum safety and optimized yield.

To size the ideal version according to your industrial needs, your volumes and your products.

FAQ – PCM Dosyfruit™